Beverage keg cleaning process control

Voltage & current measurement

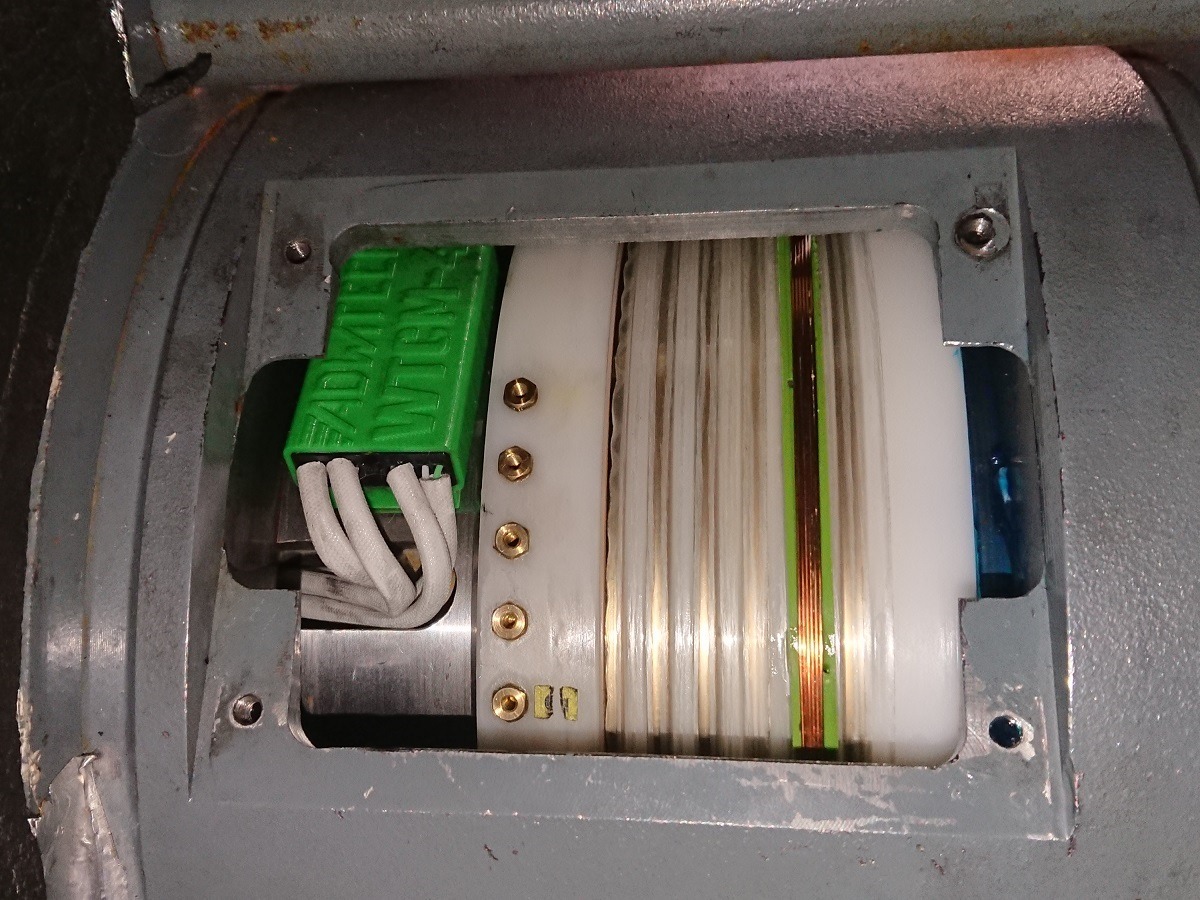

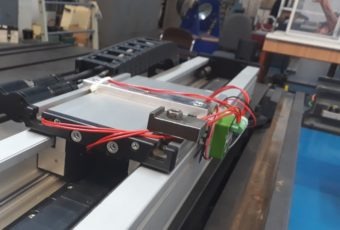

Voltage & current measurementA wireless datalogger with current loop inputs has been developed for CHEOPS spol. s.r.o. which specializes in the beverage industry. To ensure barrel cleaning process quality, internal temperature, pressure and liquid levels need to be measured.

The Wireless Datalogger Current Loop Module (WDL-CL) is capable of logging inputs as well as powering four current loop sensors through standard M12 connectors. The WDL-CL module with integrated accumulator is designed to withstand high temperatures and humid environments (IP67 rated). The user software provides easy and intuitive way of starting the logging process, to show the measured values, adjust the measurement units. The WDL-CL is also able to operate without user software control.